How Professionals Add Refrigerant To A Central Air Conditioner In 2025

Is your air conditioner running nonstop on hot summer afternoons, but the house still will not cool down? In the Rancho Cordova and Sacramento area, we see this situation every summer when the temperature climbs into the triple digits. Many homeowners understandably start searching for how to add refrigerant to their central air conditioner.

Refrigerant is not like gasoline in a car. It does not get used up during normal operation. If your system is low on refrigerant, there is almost always a leak that needs to be found and corrected. Adding more refrigerant without addressing the leak is only a temporary bandage and can create bigger, more expensive problems later.

In this guide, the team at Fox Family Heating and Air Conditioning will walk through why systems get low on refrigerant, why homeowners cannot legally recharge their own systems, how our technicians properly add refrigerant, and what to consider when deciding whether to repair or replace an older system.

Why Your AC Might Need Refrigerant

On a properly installed and sealed system, the refrigerant stays inside a closed loop of copper tubing. The same charge circulates between the indoor evaporator coil and the outdoor condenser coil year after year. The refrigerant absorbs heat inside your home, carries it outside, and rejects that heat at the outdoor unit.

Because the system is sealed, the refrigerant does not get used up. When we find a low charge, it is almost always because refrigerant has escaped somewhere in that loop. Common leak locations include:

- Braze joints and fittings at the indoor or outdoor coil

- The evaporator coil itself, especially on older equipment

- Schrader cores at the service valves

- Rub outs where copper lines have vibrated against metal

When the charge is low, several symptoms show up:

- The air coming out of the vents feels cool but not cold

- The temperature difference between supply and return is much less than the normal 18 to 22 degrees

- The system runs much longer than it used to, especially on hot afternoons

- Ice begins to form on the refrigerant lines or evaporator coil

Running in this condition causes extra stress on the compressor and can shorten the life of the entire system. That is why our technicians focus on diagnosing the root cause of the low charge, instead of just topping off refrigerant and leaving.

Can Homeowners Add Refrigerant Themselves

Some online sources make adding refrigerant sound as simple as screwing on a can and watching a gauge. In reality, safely charging a modern air conditioner requires specialized tools, training, and a working knowledge of refrigeration science.

More importantly, federal law in the United States requires anyone who handles controlled refrigerants to hold an EPA Section 608 certification. This applies to common refrigerants like R-22, R-410A, and the newer A2L refrigerants such as R-454B. Selling, purchasing, or charging these refrigerants without proper certification is not allowed.

From a safety standpoint, there are additional concerns:

- Overcharging can flood the compressor with liquid refrigerant and cause permanent damage

- Undercharging can cause the evaporator coil to freeze and restrict airflow

- Some newer refrigerants are mildly flammable and must be handled with ventilation and spark safety in mind

For these reasons, homeowners should not attempt to add refrigerant on their own. The safest and most cost-effective approach is to schedule a professional evaluation. Our technicians carry the proper gauges, scales, temperature probes, and leak detection tools to charge systems accurately and safely.

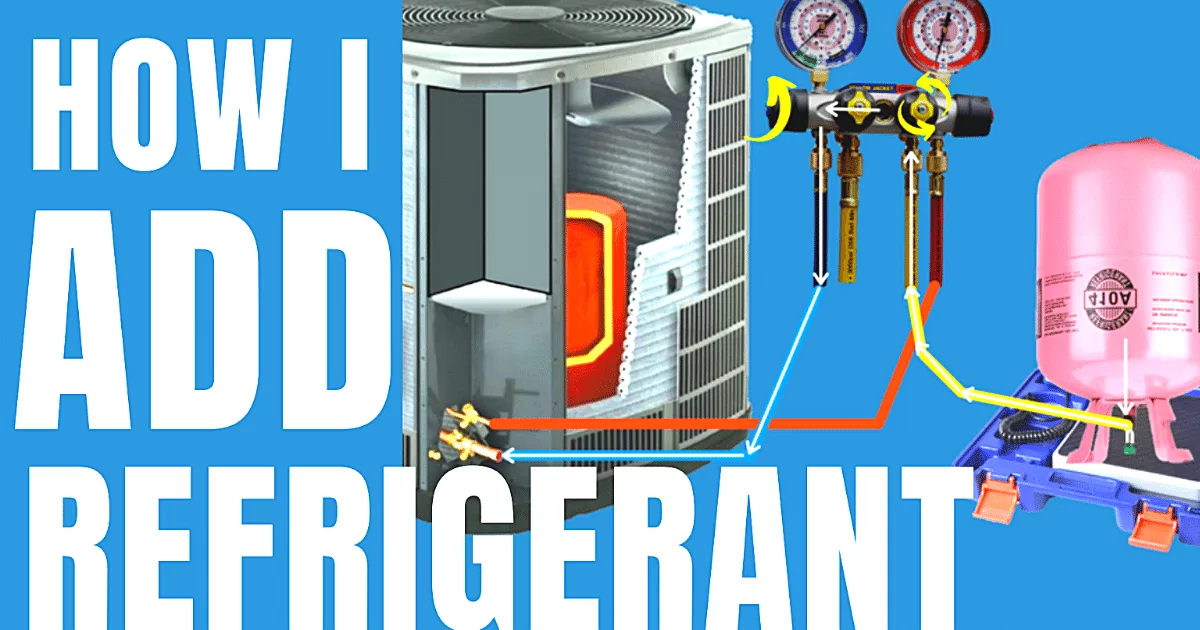

How Our Technicians Add Refrigerant

When a Fox Family Heating and Air Conditioning technician arrives at a home in Rancho Cordova, Sacramento, or anywhere in our Northern California service area, the first step is always diagnosis. We do not hook up gauges and start adding refrigerant until we understand what is going on with the system.

Here is a simplified version of the process our team follows on a typical R 410A system during a warm summer day.

1. Interview and preliminary checks

- Listen to the homeowner’s description of the problem

- Verify thermostat settings and system age

- Check the air filter, indoor blower operation, and airflow through registers

- Measure the temperature split between return and supply air

If the temperature split is much lower than the normal 18 to 22 degrees, and airflow is good, that is a strong indicator that the refrigerant charge may be low.

2. Connect gauges and temperature probes

Next, our technician connects refrigerant manifolds or digital gauges to the suction and liquid lines at the outdoor unit. Temperature probes are placed on the refrigerant lines and sometimes at the evaporator coil.

Instead of focusing only on pressures, our team looks at:

- Suction saturation temperature at the evaporator coil

- Condensing temperature at the outdoor coil

- Superheat on the suction line

- Subcooling on the liquid line

These measurements tell us what the refrigerant is doing inside the system. For example, if the suction saturation temperature is well below 32 degrees, the evaporator coil may freeze. If subcooling is very low, the system may be undercharged.

3. Confirm there is a low charge

Before adding refrigerant, our technicians rule out other causes such as:

- Dirty filters or evaporator coils restricting airflow

- Slow indoor blower speeds

- Kinked or crushed refrigerant lines

- Faulty metering devices, such as a stuck TXV

Only after these possibilities are checked will we move to adjusting the charge. This protects the customer from paying for refrigerant that the system does not actually need.

4. Weigh in refrigerant using manufacturer targets

When adding refrigerant, our technicians always charge by weight using a calibrated refrigerant scale. On a typical service call, the process looks like this:

- Place the refrigerant cylinder on the scale and zero it out

- Purge air from the charging hose

- Add refrigerant slowly through the suction side while monitoring pressures, temperatures, and compressor amperage

- Allow the system several minutes between adjustments so it can stabilize

Most modern systems use manufacturer-recommended subcooling or superheat targets. For example, a nameplate might call for 10 degrees of subcooling on a 95-degree outdoor day. The technician compares:

- High side saturation temperature from the gauge

- Actual liquid line temperature from the probe

Subcooling is the difference between those two numbers. The charge is adjusted until the measured subcooling is within the target range, usually plus or minus 2 degrees. This is a much more accurate approach than adding refrigerant until the suction line simply feels cold.

Throughout this process, we also monitor compressor amp draw and fan operation to verify that the system is operating within safe limits.

Finding And Fixing The Refrigerant Leak

Bringing the charge back to normal is only half the job. If a system is low, there is almost always a leak. Simply adding refrigerant without finding the leak means the problem will come back, and the customer will continue paying to replace refrigerant that should have stayed inside the system.

Fox Family technicians are trained to track down the source of leaks using several methods:

- Visual inspections for oil staining on copper lines and coils

- Electronic leak detectors around fittings, service valves, and coils

- Bubble solutions were brushed onto suspected leak points

- Nitrogen pressure tests with trace refrigerant when needed

Once the leak is located, we discuss repair options with the homeowner. Common repairs might include tightening or re-brazing a joint, replacing a Schrader core, or replacing a leaking evaporator coil.

In some situations, especially with older R-22 systems or heavy corrosion, the leak is not cost-effective to repair. In those cases, we have an honest conversation about replacement options and help the homeowner compare long-term costs.

Refrigerant Types In 2025

Refrigerant rules have changed significantly over the last decade, and they continue to evolve. Here is a quick overview of what homeowners in Northern California are most likely to see in 2025.

R 22

R-22 was the standard refrigerant in residential systems for many years. Production of new R-22 ended in January 2020. Any R-22 used today must come from reclaimed and recycled sources.

Because supply is limited, prices have risen sharply. In many markets, reclaimed R-22 can cost in the range of 100 to 200 dollars per pound just for the refrigerant. On an older system that is already near the end of its life, putting several pounds of expensive R-22 into a leaking system rarely makes financial sense.

R 410A

R 410A is still the dominant refrigerant in most central air conditioners installed over the last 10 to 15 years. Under the federal AIM Act, a phasedown of high global warming potential refrigerants began in 2024. That means production of R 410A will gradually decrease over time, but it will remain widely available for the near future.

In 2025, typical refrigerant costs for R 410A may fall in a general range of 80 to 150 dollars per pound, depending on market conditions. When you add labor and leak repair costs, a recharge can add up quickly, which is why we focus on finding the root cause instead of repeatedly topping off.

R 454B and other A2L refrigerants

Newer systems are beginning to use low-GWP, mildly flammable refrigerants such as R-454B. These refrigerants require updated equipment, special handling procedures, and appropriate tools. They cannot be retrofitted into older R-410A or R-22 systems.

It is important to understand that different refrigerants cannot be mixed. Each system is designed to operate with a specific refrigerant type, oil, and metering device. Mixing refrigerants can damage the compressor and void manufacturer warranties. If a system needs to be converted to a different refrigerant family, that usually means installing new equipment designed for that refrigerant.

Cost Expectations For Adding Refrigerant

Every service call is unique, but homeowners often ask for general pricing guidance. Final costs depend on the type of refrigerant, how many pounds are needed, how accessible the leak is, and whether any components have to be replaced.

Here is what many homeowners in the Rancho Cordova and Sacramento area can expect:

- Diagnostic visit and testing to confirm a low charge and check the rest of the system

- Refrigerant by the pound, with R-22 typically the most expensive and R-410A or R-454 B somewhat lower

- Labor to repair the leak, which might range from a simple service valve repair to replacing a coil

Because R-22 is reclaimed only, a significant leak on an older R-22 system can sometimes cost as much as a down payment on a new, high-efficiency system. Our role is to lay out the numbers clearly so you can make the best decision for your home and budget.

When To Repair Versus Replace

Deciding whether to repair a leaking system or replace it completely depends on several factors. When Fox Family Heating and Air Conditioning evaluates systems in Rancho Cordova and Sacramento, our technicians consider:

- The age of the system

- The type of refrigerant it uses

- The severity and location of the leak

- The overall condition of coils, the compressor, and the electrical components

- Recent repair history

In general, replacement becomes a serious consideration when:

- The system is more than 12 to 15 years old

- The unit uses R-22 and needs several pounds of reclaimed refrigerant

- The evaporator or condenser coil is extensively corroded or leaking in multiple spots

- The cost of repair approaches a significant percentage of the cost of a new, efficient system

For newer systems that use R 410A or R 454B, and where the leak is accessible and limited, repair and recharge usually make sense. We explain all options in plain language and never pressure homeowners into a decision. Our goal is to be your trusted advisor, not to push unnecessary replacements.

Conclusion And Next Steps

When your air conditioner is low on refrigerant, it is a signal that something in the sealed system is not working as it should. Refrigerant does not simply disappear. Adding more without finding the leak is only a short-term fix that often leads to repeated service calls and higher long-term costs.

In 2025, with changing refrigerant regulations and the introduction of newer A2L refrigerants, having an EPA Section 608 certified technician on your side is more important than ever. Proper charging relies on accurate measurements of superheat, subcooling, pressures, and temperatures, not on guesswork or a can from the hardware store.

Fox Family Heating and Air Conditioning serves Rancho Cordova, Sacramento, and the surrounding Northern California communities. Our technicians are trained to diagnose low refrigerant situations, locate and repair leaks, and help you decide whether repair or replacement is the smartest move for your home.

If you are noticing longer run times, warm rooms, or icing on your refrigerant lines, we are here to help. Call us at 916-877-1577 or schedule an appointment online, and our team will be on the way.

Service Request

Blog Post Form

"*" indicates required fields