Diagnosing a Bad Furnace Inducer Motor: The 4 Most Common Problems in 2025

Is your furnace clicking on and off without ever blowing warm air into your home? Does it seem like it tries to start a few times, then simply gives up for a while? When this happens, the inducer motor is often at the center of the problem.

At Fox Family Heating and Air Conditioning, our technicians see inducer motor issues every fall and winter in Rancho Cordova and Sacramento, especially around the first cold snap in late November. Sacramento Valley nights can drop into the 30s in December and January, so a furnace that will not light reliably is more than an inconvenience, it is a real comfort and safety concern.

This article explains what the inducer motor does, the warning signs homeowners notice, the four most common problems we diagnose in 2025, and what to expect when you schedule a professional repair.

What Is A Furnace Inducer Motor?

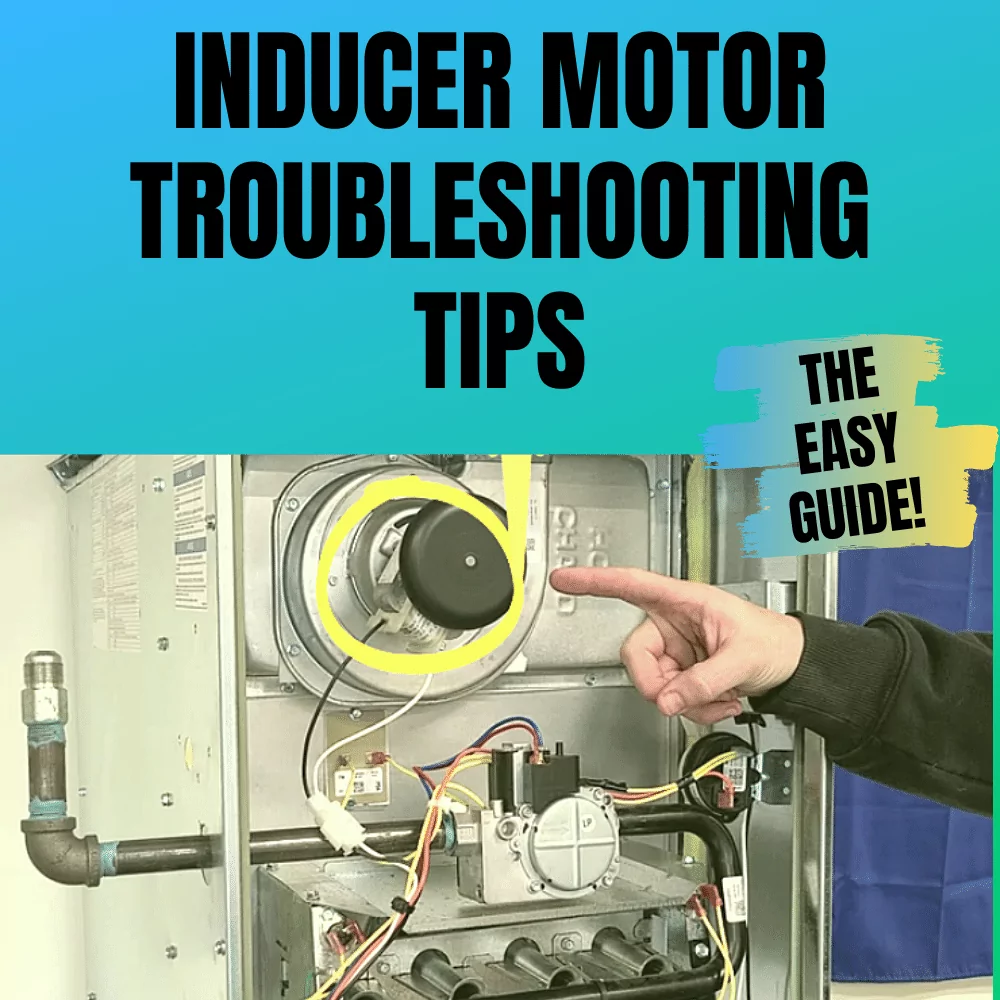

On a gas furnace, the inducer motor is the first major component that starts when your thermostat calls for heat. When the control board receives that signal, it sends about 120 volts to the inducer motor. The motor spins a small wheel, often called a squirrel cage or flywheel, that pulls combustion gases through the heat exchanger and pushes them into the vent pipe.

By doing this, the inducer motor creates a slight negative pressure or draft inside the heat exchanger. That draft clears out leftover combustion byproducts before the burners light. Cleaner air inside those hollow heat exchanger tubes allows the furnace to burn more efficiently and helps keep carbon monoxide and other gases moving safely out of your home.

A pressure switch is connected to the inducer housing with a small hose. When the inducer starts and the draft reaches the proper level, the pressure switch closes and tells the control board that it is safe to continue the ignition sequence. If the pressure switch never sees the right draft, the system will not light the burners.

Safety Warning Before You Open The Furnace

Modern gas furnaces contain high voltage, low voltage control wiring, moving parts, hot surfaces, and an open flame during operation. Reaching into the cabinet without training can lead to electrical shock, burns, or contact with moving components that can injure fingers and hands.

There is also a combustion process taking place inside the furnace. If components are miswired, removed, or reassembled incorrectly, the system may vent combustion gases poorly, which increases the risk of carbon monoxide exposure.

For these reasons, Fox Family Heating and Air Conditioning strongly recommends that inducer motor diagnostics and replacement be handled by a qualified professional. Homeowners can pay attention to symptoms and share those details with a technician, but internal troubleshooting should not be treated as a do it yourself project.

How The Inducer Fits Into The Furnace Start Up Sequence

Understanding the basic heating sequence can help explain why inducer motor problems cause so many no heat calls.

Here is the simplified order of operations on a typical gas furnace:

- Power is available to the control board.

- The thermostat calls for heat.

- The control board energizes the inducer motor with 120 volts.

- The inducer creates draft and the pressure switch closes to prove airflow.

- The hot surface igniter warms up.

- The gas valve opens and the burners light.

- The flame sensor confirms that the burners are lit.

- The blower motor turns on and sends warm air through the ducts.

If the inducer motor never starts, or if the pressure switch never proves that the draft is correct, the furnace will shut down the ignition attempt. It will usually try again a few times. After roughly three to five failed attempts, most control boards stop sending voltage to the inducer and go into a lockout mode until the issue is corrected or the power is reset.

Signs Your Inducer Motor Is Having Problems

You do not need to be an HVAC expert to notice the early warning signs of inducer trouble. Common complaints our technicians hear from homeowners include:

- The furnace clicks and the small fan in the vent area sounds weak or never starts.

- The furnace tries to start several times, then shuts down and blows only room temperature air.

- A burning smell or hot, metallic odor comes from the furnace area when it tries to run.

- The furnace is much louder than it used to be, with new rattling, scraping, or wobbling sounds near the vent connection.

- The system used to light on the first try but now needs multiple attempts or runs for a short time, then shuts off again.

If you are noticing any of these symptoms, there is a good chance the inducer motor or one of its supporting components is having problems.

The 4 Most Common Inducer Motor Problems In 2025

Our technicians see many different furnace issues, but inducer motor failures tend to fall into four main categories. Each one affects the furnace in a slightly different way.

1. Seized Bearings (Motor Will Not Spin)

Inside every inducer motor are bearings that support the motor shaft. Over time, heat, moisture, and age can cause those bearings to dry out or corrode. When that happens, the shaft becomes harder and harder to turn until it eventually locks in place.

From a homeowner perspective, this usually looks like a furnace that tries to start but never gets past the first step. The control board sends 120 volts to the inducer motor, and the base of the motor may even feel warm or hot, but the wheel does not move. If you were to look inside the cabinet, the squirrel cage or flywheel would not spin when the furnace calls for heat.

Because the motor cannot move, the pressure switch never sees enough draft to close, and the control board quickly shuts down the ignition attempt. After several tries, the furnace locks out until the power is reset or the issue is fixed.

In almost every case, seized bearings mean the inducer motor needs to be replaced. Lubricants cannot reach sealed motor bearings effectively once they have worn out, and forcing a locked motor to run can overheat windings and damage the control board.

2. Open Motor Windings (Electrical Failure)

Inducer motors contain electrical windings that create the magnetic fields needed to turn the motor shaft. On some failed motors, one of these windings opens internally, which means there is a break in the circuit.

When a motor has an open winding, the control board still sends 120 volts, but the motor cannot create the magnetic field needed to start turning. Sometimes the motor will buzz, hum, or twitch slightly, then stop. Other times, it will sit completely still even though proper voltage is present.

Homeowners often notice repeated start attempts and lockouts with no obvious mechanical obstruction. A technician will usually verify power to the motor, then test the windings with a meter to confirm the failure. Once a winding opens, repair is not practical. The inducer assembly is replaced as a whole unit to restore safe operation.

3. Bad Capacitor

Many inducer motors use a capacitor to provide an extra boost of electrical energy when the motor starts and to help regulate voltage while it runs. When that capacitor fails, the motor may have difficulty starting, run weakly, or fail to run at all.

From the homeowner point of view, this can look very similar to a seized or electrically failed motor. You may hear a humming sound as the furnace tries to start, followed by a shutdown and retry. In some cases the motor will start turning slowly, then stall out.

A technician will test the capacitor with a meter to confirm whether it is within its rated microfarad range. If the capacitor is weak or completely failed, replacing it is often enough to bring the inducer motor back to life, as long as the motor windings and bearings are still in good shape.

Because both the motor and capacitor work together, it is common for our technicians to evaluate both at the same time during a service call.

4. Unusual Noises (Motor On Borrowed Time)

One of the earliest signs that an inducer motor is on borrowed time is a change in sound. Homeowners describe everything from rattling and clanking to chattering, pinging, or a wobbling vibration that was never there before.

These noises can be caused by worn bearings, a loose or damaged squirrel cage, a warped flywheel, or mounting hardware that has loosened over time. Even if the motor still starts and the furnace appears to heat the home, the system is no longer operating the way the manufacturer intended.

If the motor is shaking, wobbling, or making loud mechanical noises, it is at higher risk of sudden failure. It can also place extra stress on the pressure switch, vent connections, and surrounding components.

Our recommendation is to treat unusual inducer motor noises as an early warning. Having the system inspected and repaired before the motor stops completely is often more convenient and may help prevent a no-heat emergency on a cold Sacramento Valley night.

Why The Inducer Motor Has To Work First

Homeowners sometimes want reassurance that replacing the inducer motor will fix everything. The honest answer is that no technician can see how the rest of the furnace operates until the inducer is running properly.

The inducer motor starts the entire heating sequence. Until it pulls the right draft, closes the pressure switch, and allows the burners to light, there is no way to test components further down the line such as the gas valve, flame sensor, or main blower motor.

Most of the time, once the inducer problem is corrected, the rest of the furnace works normally. However, multiple issues can exist at once, especially on older systems. Fox Family Heating and Air Conditioning technicians make a point of explaining this clearly so homeowners understand that the inducer repair is the first step in a complete diagnosis, not a guarantee that no other parts will ever need attention.

Repair Or Replace The Inducer Motor?

In theory, an electric motor can be rebuilt. In practice, most residential furnace inducer motors are sealed units that are not designed for field repair. The housings are often riveted or welded, the bearings are sealed, and the motor is built into a specific assembly that matches the furnace model and venting design.

Because of this, the most reliable solution in 2025 is usually to replace the inducer assembly as a complete unit. That replacement restores the motor, wheel, and housing to manufacturer specifications, which helps maintain safe venting and proper draft levels.

During a service visit, our technicians will:

- Confirm that the inducer motor is receiving proper voltage.

- Test the capacitor, if one is present.

- Inspect the wheel and housing for damage or debris.

- Verify that the pressure switch and tubing are in good condition.

- Recommend replacement if the motor is seized, has open windings, or is making unsafe levels of noise.

Before work begins, homeowners receive clear, up front pricing and an estimated timeline for repair. If a specific inducer assembly needs to be ordered from the manufacturer, our office will coordinate scheduling so the part can be installed as soon as it arrives.

When To Call A Professional

Because the inducer motor is tied directly to combustion and venting, any problem with this component is considered a safety related issue. You should contact a qualified HVAC company for your furnace if:

- The furnace attempts to start several times, then shuts down with no heat.

- You hear new grinding, rattling, or wobbling noises from the vent connection or furnace cabinet.

- You smell gas near the furnace at any time.

- You see visible damage, rust, or water around the inducer or vent piping.

- You have to reset the breaker or power switch frequently to get the furnace running again.

Residents in Rancho Cordova, Sacramento and nearby Sacramento Valley communities can call Fox Family Heating and Air Conditioning for same day or next day appointments in most cases. Our technicians arrive with the tools and testing equipment needed to diagnose inducer motor problems safely and accurately.

What To Expect During A Service Call

When you schedule a visit for a suspected inducer motor issue, your technician will typically:

- Talk with you about the symptoms you have noticed, such as noises, smells, or repeated shutdowns.

- Inspect the furnace, venting, and electrical connections for visible problems.

- Verify the furnace start up sequence and confirm that 120 volts is reaching the inducer motor.

- Check draft and pressure switch operation, including the tubing and ports.

- Test the inducer motor winding and capacitor where applicable.

- Confirm whether the motor can be safely kept in service or needs replacement.

- Review findings with you, explain repair options, and answer questions before proceeding.

After the repair, the technician will run the furnace through several complete heating cycles to confirm that the inducer, pressure switch, burners, and blower are all working properly. This final check helps ensure that your system operates to manufacturer specifications and that there are no additional hidden issues.

Conclusion: Stay Warm And Safe This Winter

Inducer motor problems are one of the most common reasons furnaces in the Sacramento Valley fail to start or stay running. Whether the issue is seized bearings, open windings, a failed capacitor, or a motor that is making loud new noises, addressing it promptly helps protect your home, your comfort, and your energy bills as a SMUD or PG&E customer.

If your furnace is struggling to light or making unfamiliar sounds, do not wait for the next cold front to roll through. The team at Fox Family Heating and Air Conditioning is ready to help homeowners in Rancho Cordova, Sacramento, and surrounding communities get their heat back on quickly and safely.

Ready to schedule service or have questions about your furnace inducer motor? Call us at 916-877-1577 or book an appointment online with us.

Don’t miss our video series on this topic:

Service Request

Blog Post Form

"*" indicates required fields